Enhancing Performance and Reliability with Advanced Durable Shielded Cable Designs

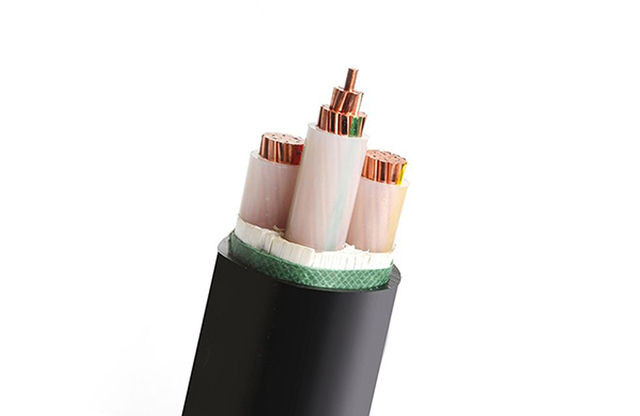

Introduction In today's rapidly evolving technological landscape, the demand for high-performance, reliable, and durable shielded cables is more crucial than ever before. Shielded cables play a vital role in ensuring the secure and efficient transmission of data, power, and signals in a wide range of applications, from industrial machinery and automation systems to telecommunications infrastructure and aerospace equipment. The design and construction of shielded cables are critical factors that determine their performance, durability, and resistance to external interference. This article will delve into the world of durable shielded cable designs, exploring the latest advancements, best practices, and key considerations for achieving optimal performance and reliability. Understanding Shielded Cables Shielded cables are designed to protect transmitted signals from external electromagnetic interference (EMI) and radio-frequency interference (RFI). They consist of one or more insulated conductors surrounded by a metallic shield, which acts as a barrier to block or absorb external electromagnetic fields. The shielded construction helps minimize signal distortion, crosstalk, and noise, ensuring clean and reliable signal transmission over long distances. There are various types of shielded cables available, each tailored to specific applications and performance requirements. Common types include twisted pair cables, coaxial cables, and fiber optic cables, each offering unique advantages in terms of signal integrity, bandwidth, and EMI protection. The choice of shielded cable type depends on factors such as the operating environment, data transmission speed, and frequency range. Importance of Durable Shielded Cable Designs Durable shielded cable designs are essential for maintaining signal integrity, minimizing downtime, and ensuring long-term reliability in critical applications. The following are some key reasons why durable shielded cable designs are crucial:  1. Robust Construction: Durable shielded cables feature a rugged construction that can withstand harsh environmental conditions, mechanical stress, and temperature extremes. A robust outer jacket, high-quality insulation materials, and secure shielding enhance the cable's durability and resistance to physical damage. 2. Longevity: Durable shielded cables are designed to have a long service life, reducing the need for frequent replacements and maintenance. By investing in high-quality, long-lasting cables, organizations can save time and resources in the long run. 3. Enhanced Performance: Durable shielded cables offer superior performance in terms of signal attenuation, impedance control, and noise rejection. By minimizing signal loss and distortion, these cables support high-speed data transmission and ensure reliable connectivity in demanding applications. 4. EMI Protection: Shielded cables with effective shielding designs provide robust protection against electromagnetic interference, preventing external signals from disrupting the transmitted data. This is particularly critical in environments with high EMI levels, such as industrial facilities and power plants. Advanced Features in Durable Shielded Cable Designs Advancements in materials science, manufacturing technologies, and design methodologies have led to the development of innovative features in durable shielded cable designs. These advanced features enhance the performance, reliability, and versatility of shielded cables, catering to the evolving needs of modern applications. Some of the notable advanced features in durable shielded cable designs include: 1. High-Flexibility Construction: High-flexibility shielded cables are designed to withstand repeated bending, twisting, and flexing without compromising performance. These cables are ideal for applications that require frequent motion or tight bending radii, such as robotics, automation systems, and portable devices. 2. Low-Smoke, Zero-Halogen (LSZH) Materials: LSZH shielded cables are manufactured using materials that emit minimal smoke and toxic gases in the event of a fire. These cables are commonly used in public buildings, transportation systems, and other spaces where fire safety and environmental concerns are paramount. 3. Armored Protection: Armored shielded cables feature an additional layer of protective armor, such as steel or aluminum, to enhance resistance to physical damage, abrasion, and rodent attacks. These cables are suitable for outdoor, underground, and industrial applications where mechanical protection is essential. 4. Enhanced EMI Shielding: Advanced shielding technologies, such as braided shields, foil shields, and combination shields, provide superior EMI protection and signal integrity. By optimizing the shielding design and materials, shielded cables can effectively block external interference and ensure reliable data transmission in noisy environments. 5. High-Temperature Resistance: Shielded cables with high-temperature-resistant insulation materials can withstand elevated temperatures without degradation, making them suitable for applications in industrial ovens, automotive engines, and other high-heat environments. read here for Designing Durable Shielded Cables Designing durable shielded cables requires careful consideration of various factors, including the application requirements, environmental conditions, signal characteristics, and regulatory standards. By following best practices in cable design, manufacturers can create high-quality shielded cables that meet the performance and reliability expectations of customers. Some key best practices for designing durable shielded cables include: 1. Selecting Appropriate Shielding Type: Choose the right type of shielding (e.g., braided, foil, combination) based on the EMI/RFI protection requirements of the application. Consider factors such as signal frequency, noise levels, and installation environment when selecting the shielding type. 2. Using High-Quality Materials: Use high-grade materials for the cable conductors, insulation, shielding, and jacket to ensure durability, flexibility, and electrical performance. Select materials that are compatible with the operating conditions and performance specifications of the application. 3. Optimizing Shielding Coverage: Ensure sufficient shielding coverage to effectively block external interference and maintain signal integrity. The shielding coverage should be optimized based on the signal frequency range, noise sources, and attenuation requirements of the application. 4. Minimizing Signal Loss: Design the cable with low-loss materials, precise impedance control, and minimal crosstalk to minimize signal attenuation and distortion. Properly matched impedance throughout the cable length is critical for maintaining signal integrity. 5. Considering Environmental Factors: Evaluate the operating environment for factors such as temperature variations, moisture exposure, chemical exposure, and mechanical stress. Choose cable materials and constructions that can withstand these environmental challenges without performance degradation. 6. Conducting Rigorous Testing: Perform comprehensive testing of the shielded cable design to validate performance, durability, and compliance with industry standards. Conduct tests for electrical properties, mechanical strength, EMI shielding effectiveness, and environmental resistance. Applications of Durable Shielded Cable Designs Durable shielded cables find applications across a wide range of industries and sectors where reliable signal transmission, EMI protection, and durability are essential. Some common applications of durable shielded cable designs include: 1. Industrial Automation: Shielded cables are used in industrial automation systems, robotics, and machinery to ensure reliable communication between sensors, actuators, controllers, and other components. The robust construction and EMI protection of shielded cables make them ideal for harsh industrial environments. 2. Telecommunications Infrastructure: Shielded cables are deployed in telecommunications networks, data centers, and broadband installations to support high-speed data transmission and protect against external interference. Fiber optic shielded cables are commonly used for long-distance data communication. 3. Aerospace and Defense: Shielded cables are critical components in aerospace and defense systems, including avionics, radar systems, aircraft wiring, and military vehicles. These cables must meet stringent performance, reliability, and safety standards to operate in demanding aerospace environments. 4. Medical Devices: Shielded cables are used in medical devices, diagnostic equipment, and imaging systems to ensure accurate signal transmission and patient safety. The high-quality construction and EMI shielding of shielded cables are essential for medical applications. 5. Automotive Electronics: Shielded cables play a vital role in automotive electronics, supporting applications such as engine control units, sensors, infotainment systems, and on-board diagnostics. These cables must withstand temperature variations, vibration, and electromagnetic interference in automotive environments. Conclusion Durable shielded cable designs are indispensable components in modern technology, providing essential connectivity, signal integrity, and EMI protection in a wide range of applications. By leveraging advanced materials, innovative design features, and best practices in cable design, manufacturers can create high-performance shielded cables that meet the demands of today's complex and challenging environments. As industries continue to push the boundaries of innovation and connectivity, the role of durable shielded cables will remain paramount in ensuring reliable and efficient data transmission. By investing in quality shielded cables and adhering to best practices in cable design, organizations can enhance performance, reliability, and longevity in their critical systems and applications.

1. Robust Construction: Durable shielded cables feature a rugged construction that can withstand harsh environmental conditions, mechanical stress, and temperature extremes. A robust outer jacket, high-quality insulation materials, and secure shielding enhance the cable's durability and resistance to physical damage. 2. Longevity: Durable shielded cables are designed to have a long service life, reducing the need for frequent replacements and maintenance. By investing in high-quality, long-lasting cables, organizations can save time and resources in the long run. 3. Enhanced Performance: Durable shielded cables offer superior performance in terms of signal attenuation, impedance control, and noise rejection. By minimizing signal loss and distortion, these cables support high-speed data transmission and ensure reliable connectivity in demanding applications. 4. EMI Protection: Shielded cables with effective shielding designs provide robust protection against electromagnetic interference, preventing external signals from disrupting the transmitted data. This is particularly critical in environments with high EMI levels, such as industrial facilities and power plants. Advanced Features in Durable Shielded Cable Designs Advancements in materials science, manufacturing technologies, and design methodologies have led to the development of innovative features in durable shielded cable designs. These advanced features enhance the performance, reliability, and versatility of shielded cables, catering to the evolving needs of modern applications. Some of the notable advanced features in durable shielded cable designs include: 1. High-Flexibility Construction: High-flexibility shielded cables are designed to withstand repeated bending, twisting, and flexing without compromising performance. These cables are ideal for applications that require frequent motion or tight bending radii, such as robotics, automation systems, and portable devices. 2. Low-Smoke, Zero-Halogen (LSZH) Materials: LSZH shielded cables are manufactured using materials that emit minimal smoke and toxic gases in the event of a fire. These cables are commonly used in public buildings, transportation systems, and other spaces where fire safety and environmental concerns are paramount. 3. Armored Protection: Armored shielded cables feature an additional layer of protective armor, such as steel or aluminum, to enhance resistance to physical damage, abrasion, and rodent attacks. These cables are suitable for outdoor, underground, and industrial applications where mechanical protection is essential. 4. Enhanced EMI Shielding: Advanced shielding technologies, such as braided shields, foil shields, and combination shields, provide superior EMI protection and signal integrity. By optimizing the shielding design and materials, shielded cables can effectively block external interference and ensure reliable data transmission in noisy environments. 5. High-Temperature Resistance: Shielded cables with high-temperature-resistant insulation materials can withstand elevated temperatures without degradation, making them suitable for applications in industrial ovens, automotive engines, and other high-heat environments. read here for Designing Durable Shielded Cables Designing durable shielded cables requires careful consideration of various factors, including the application requirements, environmental conditions, signal characteristics, and regulatory standards. By following best practices in cable design, manufacturers can create high-quality shielded cables that meet the performance and reliability expectations of customers. Some key best practices for designing durable shielded cables include: 1. Selecting Appropriate Shielding Type: Choose the right type of shielding (e.g., braided, foil, combination) based on the EMI/RFI protection requirements of the application. Consider factors such as signal frequency, noise levels, and installation environment when selecting the shielding type. 2. Using High-Quality Materials: Use high-grade materials for the cable conductors, insulation, shielding, and jacket to ensure durability, flexibility, and electrical performance. Select materials that are compatible with the operating conditions and performance specifications of the application. 3. Optimizing Shielding Coverage: Ensure sufficient shielding coverage to effectively block external interference and maintain signal integrity. The shielding coverage should be optimized based on the signal frequency range, noise sources, and attenuation requirements of the application. 4. Minimizing Signal Loss: Design the cable with low-loss materials, precise impedance control, and minimal crosstalk to minimize signal attenuation and distortion. Properly matched impedance throughout the cable length is critical for maintaining signal integrity. 5. Considering Environmental Factors: Evaluate the operating environment for factors such as temperature variations, moisture exposure, chemical exposure, and mechanical stress. Choose cable materials and constructions that can withstand these environmental challenges without performance degradation. 6. Conducting Rigorous Testing: Perform comprehensive testing of the shielded cable design to validate performance, durability, and compliance with industry standards. Conduct tests for electrical properties, mechanical strength, EMI shielding effectiveness, and environmental resistance. Applications of Durable Shielded Cable Designs Durable shielded cables find applications across a wide range of industries and sectors where reliable signal transmission, EMI protection, and durability are essential. Some common applications of durable shielded cable designs include: 1. Industrial Automation: Shielded cables are used in industrial automation systems, robotics, and machinery to ensure reliable communication between sensors, actuators, controllers, and other components. The robust construction and EMI protection of shielded cables make them ideal for harsh industrial environments. 2. Telecommunications Infrastructure: Shielded cables are deployed in telecommunications networks, data centers, and broadband installations to support high-speed data transmission and protect against external interference. Fiber optic shielded cables are commonly used for long-distance data communication. 3. Aerospace and Defense: Shielded cables are critical components in aerospace and defense systems, including avionics, radar systems, aircraft wiring, and military vehicles. These cables must meet stringent performance, reliability, and safety standards to operate in demanding aerospace environments. 4. Medical Devices: Shielded cables are used in medical devices, diagnostic equipment, and imaging systems to ensure accurate signal transmission and patient safety. The high-quality construction and EMI shielding of shielded cables are essential for medical applications. 5. Automotive Electronics: Shielded cables play a vital role in automotive electronics, supporting applications such as engine control units, sensors, infotainment systems, and on-board diagnostics. These cables must withstand temperature variations, vibration, and electromagnetic interference in automotive environments. Conclusion Durable shielded cable designs are indispensable components in modern technology, providing essential connectivity, signal integrity, and EMI protection in a wide range of applications. By leveraging advanced materials, innovative design features, and best practices in cable design, manufacturers can create high-performance shielded cables that meet the demands of today's complex and challenging environments. As industries continue to push the boundaries of innovation and connectivity, the role of durable shielded cables will remain paramount in ensuring reliable and efficient data transmission. By investing in quality shielded cables and adhering to best practices in cable design, organizations can enhance performance, reliability, and longevity in their critical systems and applications.